Casting Design - Draft

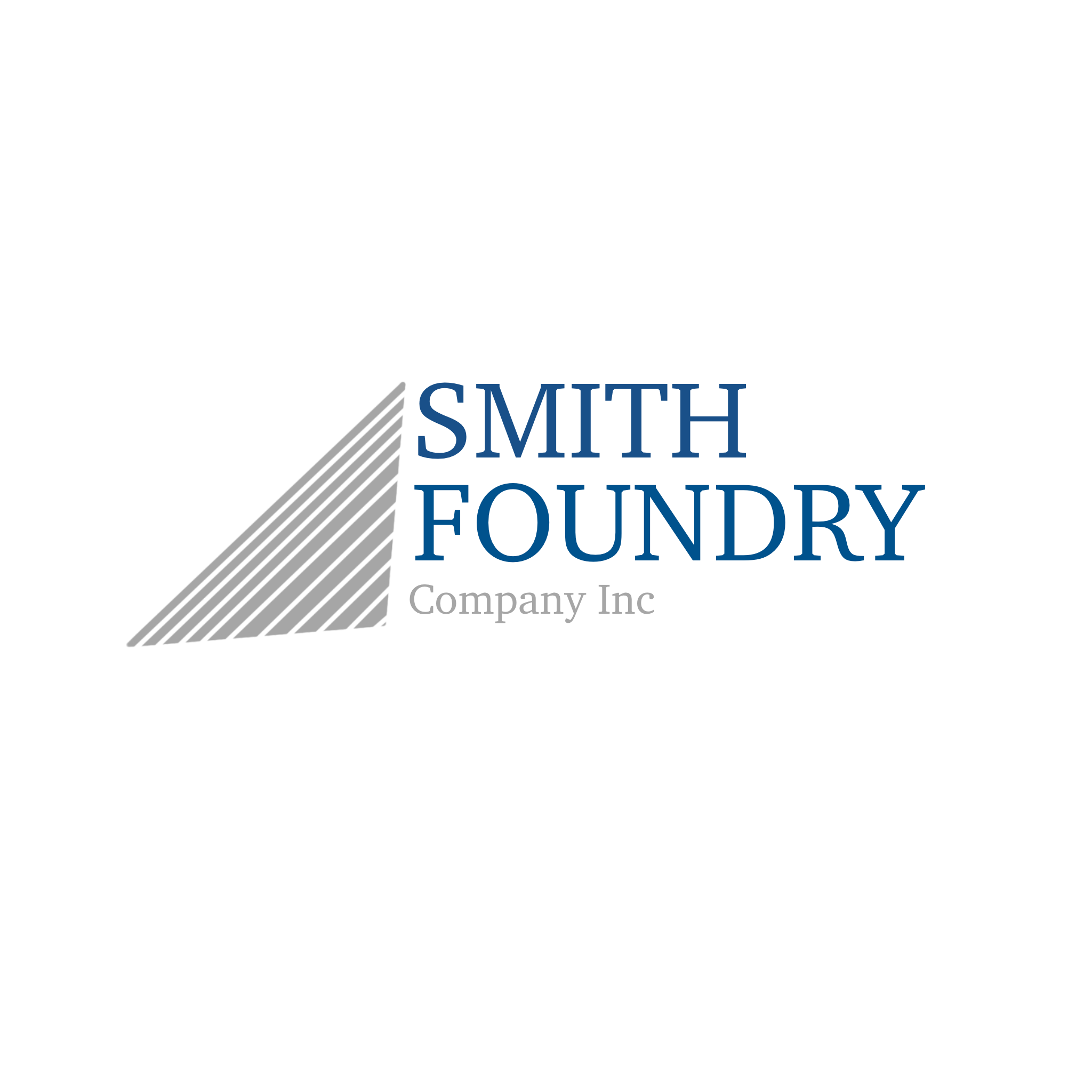

Draft is required for the pattern to draw out of the sand mold. The above picture shows an extreme example, but illustrates the importance of draft. It is important for the customer to understand that draft is required and to allow for it in the casting design. Too little draft can increase costs by causing poor molding quality, resulting in excessive grinding time and in some cases requiring the addition of cores.

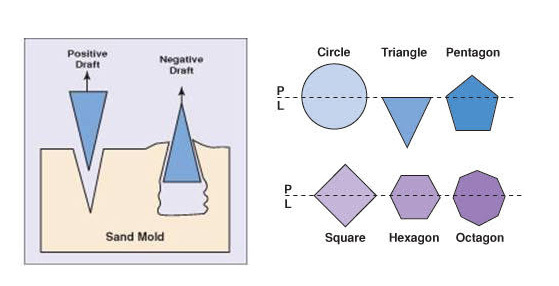

Not all casting designs require the addition of draft. These shapes all have “natural draft” and don’t require changes.

Plus or minus draft? Normal convention is to add material to create draft (plus draft). Dimension is held at the point furthest from the parting line and material is added for draft. Outside dimensions get larger, inside dimensions get smaller. In situations where clearance is required, such as an as-cast bolt hole, material is taken away to create draft (minus draft). Dimension is held at or closest to the parting line and material is taken away for draft. Outside dimensions get smaller, inside dimensions get larger. It is always a good idea to have some sort of notation on the drawing regarding the draft desired, especially when minus draft conditions are desired.

How much draft is needed? Draft is usually expressed in degrees, but in actuality it is the linear dimension that is important. In green sand, automatic molding, the minimum amount of draft required is 0.03” material. The shorter the length of draw, the greater the degrees of draft needed to achieve 0.03” draft. A ½” draw length will require a minimum of 3 degrees draft angle, where 1” draw length will only require 2 degrees. 2” and more only require a minimum of 1 degree.

If you have questions about draft or need some design assistance, our engineering team is happy to work with you on getting your casting drafted properly.

Larry Kramer

VP, Engineering

Follow us on LinkedIn to get future updates and other helpful information.